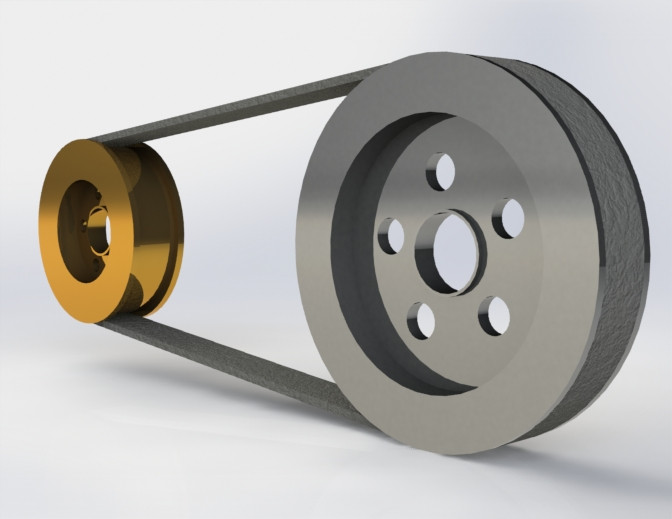

Introducing Flat Belt Pulley for Chemical Processing Equipment

Keywords: Flat Belt Pulley, Chemical Processing Equipment

1. High-Quality Material: Our Flat Belt Pulleys are made from durable materials that are suitable for use in chemical processing equipment, ensuring longevity and reliability.

2. Precision Engineering: Each Flat Belt Pulley is meticulously designed and manufactured to meet the specific requirements of chemical processing applications, guaranteeing optimal performance.

3. Corrosion Resistance: The Flat Belt Pulley is designed to withstand harsh chemical environments, making it ideal for use in chemical processing equipment where corrosion is a concern.

4. Customizable Options: We offer a range of customizable options for our Flat Belt Pulleys, allowing you to tailor the pulley to your exact specifications and requirements.

5. Cost-Effective Solution: Our Flat Belt Pulleys provide a cost-effective solution for chemical processing equipment, offering high performance at a competitive price point.

Features of Flat Belt Pulley:

– Durable material construction

– Precision engineered design

– Corrosion-resistant coating

– Customizable options available

– Cost-effective solution for chemical processing equipment

Application of Flat Belt Pulley for Chemical Processing Equipment:

1. Chemical Resistance: The Flat Belt Pulley is designed to withstand exposure to various chemicals commonly found in chemical processing equipment, ensuring reliable performance.

2. Precision Alignment: The Flat Belt Pulley ensures precise alignment of belts in chemical processing equipment, reducing wear and tear on components.

3. Efficient Power Transmission: The Flat Belt Pulley facilitates smooth and efficient power transmission in chemical processing equipment, enhancing overall operational efficiency.

4. Low Maintenance: The Flat Belt Pulley requires minimal maintenance, reducing downtime and ensuring continuous operation of chemical processing equipment.

5. Longevity: The durable construction of the Flat Belt Pulley ensures long-lasting performance in harsh chemical processing environments, providing a reliable solution for your equipment.

How to Choose a Suitable Flat Belt Pulley:

1. Consider Chemical Compatibility: Choose a Flat Belt Pulley that is compatible with the chemicals used in your processing equipment.

2. Evaluate Load Capacity: Select a Flat Belt Pulley that can handle the load requirements of your specific application.

3. Assess Size and Design: Ensure the Flat Belt Pulley is the right size and design to fit your equipment and align properly with other components.

4. Review Customization Options: Look for customization options that allow you to tailor the Flat Belt Pulley to your exact specifications.

5. Compare Pricing: Consider the cost of the Flat Belt Pulley and choose a solution that offers the best value for your budget.

How do flat belts stay on pulleys?

1. The flat belts are held in place on the pulleys by friction between the belt and the pulley surface.

2. Tension in the belt helps to keep it securely on the pulley, preventing slippage during operation.

3. Proper alignment of the pulleys ensures that the belt stays in place and transfers power efficiently.

4. Belt tensioning devices can be used to adjust the tension in the belt and maintain its position on the pulley.

5. Regular maintenance and inspection of the belt and pulley system help to ensure that the belt stays securely on the pulley.

What is the flat belt mechanism?

1. The flat belt mechanism consists of a flat belt that wraps around two or more pulleys to transmit power between them.

2. The flat belt is typically made of rubber or synthetic material and is flexible to adapt to the pulley’s shape.

3. Tension in the belt helps to maintain contact with the pulleys and transfer power efficiently.

4. Flat belts are commonly used in industrial applications for power transmission due to their simplicity and cost-effectiveness.

5. Proper maintenance of the flat belt mechanism is essential to ensure smooth operation and prevent premature wear.

About HZPT

At HZPT, we are a leading manufacturer with a strong product development team and experienced workers, specializing in customized parts for various industries. Our commitment to quality and precision has earned us a reputation for excellence in Europe and the United States. We offer the best service, highest product quality, and competitive prices to meet our customers’ needs.